Among the most popular LCD display technology COG i.e chip on glass LCD displays are used in various applications and different industries on large scale. The COG displays are compact in size, have high resolution and are cost effective. In this blog post, we will discuss the COG LCD technology focused on their Pros and Cons.

Lets Understand What is COG Display

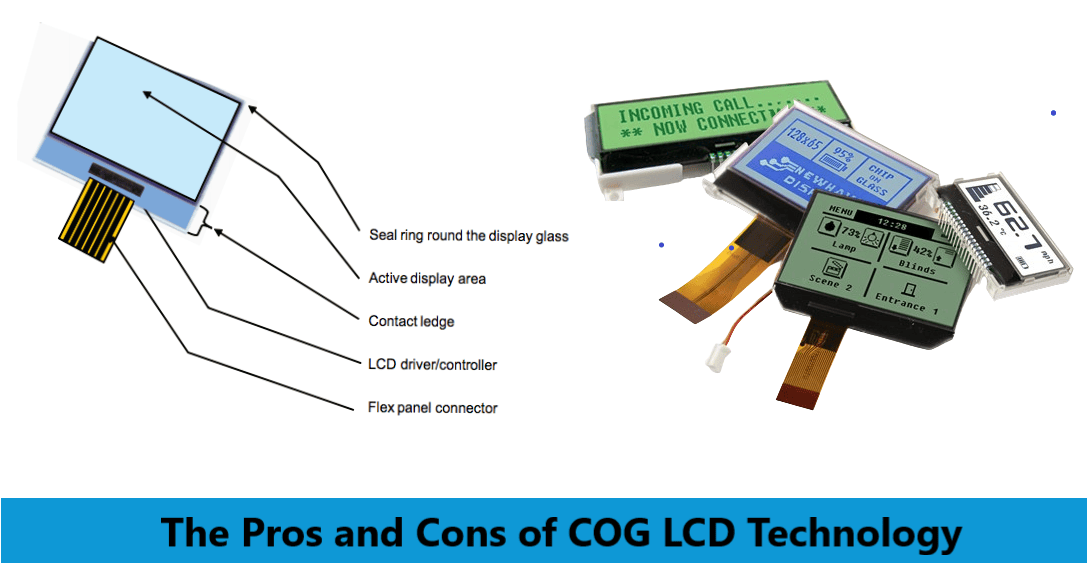

COG (Chip on Glass) Display

In contrast, COG modules position the LCD driver directly onto an overlapping edge of one of the glass plates composing the LCD. This makes the display less than 3 mm thick, where all connections from the LCD driver to the LCD are totally shielded from the external surrounding. With COG modules, each connection requires only a single bond, ensuring optimal reliability of the module.

Lets see specifications of COG LCD module display available at our Campus Component Store.

128X64 (S) COG White Display Small Size:

Our 128X64 (S) COG White Display, designed for professional industrial applications, offers a compact monochrome LCD solution. Ideal for a range of industries, including digital panel meters, UPS systems, inverters, multi-function meters, POS machines, fuel dispensers, oil dispensers, gas dispensers, flow meters, KWH meters, energy meters, water meters, gas meters, smart meters, and clocks, our COG Graphic LCD Module 128*64 comes in various models ready for use or can be customized to meet specific requirements. We offer flexibility in interface options such as I2C and Serial, and provide a range of font choices to suit your needs.

128X64 (S) COG White Display Small Size Features:

LCD Type: FSTN, Positive Transflective

Operating Voltage: Vdd- 3V

Viewing Direction: 6 O'clock

Drive Method: 1/65 Duty, 1/9 Bias

Operating Voltage: -20c to +70c

Storage Temp: -30C to +80C

Connector Type: COG+20Pin

Driver IC: ST7567S

Backlight: White

128X64 (S) COG White Display Small Size Specifications:

Model No: SDGG12864-58

Outline Dimension(mm): 63.20x41.70x5.10

Viewing Area(mm): 50.00x25.00

Color available: Grey, Yellow-green, Blue

IC: ST7567

IC Package: COG

Interface: Parallel/SPI

Now let's discuss the Pros and Cons of COG LCD Technology.

Pros of COG LCD Technology

1. High Resolution

COG LCD modules have exceptional resolution capabilities, guaranteeing a sharp and smooth display of information. Through technological advancements, these modules achieve high pixel densities, enabling the complex details and maximizing the user experience.

2. Wide Viewing Angle

COG LCD modules offer a broader viewing angle, this ensures that displayed content remains visible from various angles. This feature has applications requiring multiple users to view the display simultaneously, such as public information displays and automotive dashboards.

3. Cost-Effective

COG LCD modules stand out in the market for their low cost availability. Because the driver IC onto the glass substrate reduces overall manufacturing costs, making them an economical choice for various industries. Their affordable cost makes them well-suited for large-scale production and mass-market applications.

4. Compact Design

A standout feature of COG LCD modules is their compact design. By integrating the driver IC directly onto the glass substrate, the need for additional PCBs is eliminated, resulting in a thinner and lighter display module. This feature makes them suitable for space-limited applications such as portable devices and wearables.

5. Low Power Consumption

COG LCD modules have minimal power consumption, this makes them exceptionally energy-efficient. This feature proves particularly advantageous for battery-operated devices, as it long battery life and maximizes the overall user experience.

6. Enhanced Reliability

The direct integration of driver ICs onto the glass substrate enhances the display’s robustness and reliability by reducing the number of external components which are responsive to environmental factors and mechanical stress. This benefits in improved resistance to shock, vibration, and temperature variations, making COG LCDs suitable for complex applications.

Cons of COG LCD Technology

1. Restricted Customization Options

COG LCD modules have limited flexibility for customization. The integration of the driver IC onto the glass substrate limits the ability to change the module's layout or add additional components. This limitation may present challenges for applications which require specific design modifications or additional functionalities.

2. Responsive to Mechanical Strain

Due to their compact size and direct integration of the driver IC onto the glass substrate, COG LCD modules are more vulnerable to mechanical stress. Excessive bending or pressure can cause damage to the delicate components, which may result in display malfunctions or complete failure. Careful handling and protective measures are important to handle these displays.

3. Restricted Operating Temperature Range

COG LCD modules have a restricted operating temperature range compared to alternative display technologies. Extreme temperatures can adversely affect the module's performance and longevity, this makes it less suitable for applications requiring operation in harsh environmental conditions.

4. Complex Manufacturing Process

The integration of driver ICs directly onto the glass substrate is a complex manufacturing process involving precise alignment, bonding, and testing procedures. This complexity leads to higher production costs and longer lead times, making COG LCDs less economical for low-volume production runs.

5. Limited Scalability

While COG LCD technology offers significant advantages in terms of compactness and reliability, it may not be easily scalable for larger display sizes due to the constraints by the integration of driver ICs onto the glass. This limits its applicability in certain markets requiring large displays such as televisions and digital boards.

Also Read: The Pros and Cons of COB LCD Technology

Conclusion

Thus above we discussed multiple aspects about COG LCD Technology and their pros and cons. Understanding these pros and cons is important while selecting the proper display technology for your applications. In conclusion, for industrial, automotive, and portable equipment devices, integrating COG LCD modules into your projects serves as an excellent choice. These modules offer significant advantages over traditional LCD modules with packaged LCD drivers. With their thinner and compact size, enhanced reliability, flexibility, and cost-effectiveness, COG modules present a good solution for diverse display requirements.

Thus using COG LCD technology can optimize performance in various applications.

If you are looking for a COG LCD Display then Campus Component is your one stop solution for electronic components online where you can get COG displays from top brands like Sinda and many more.