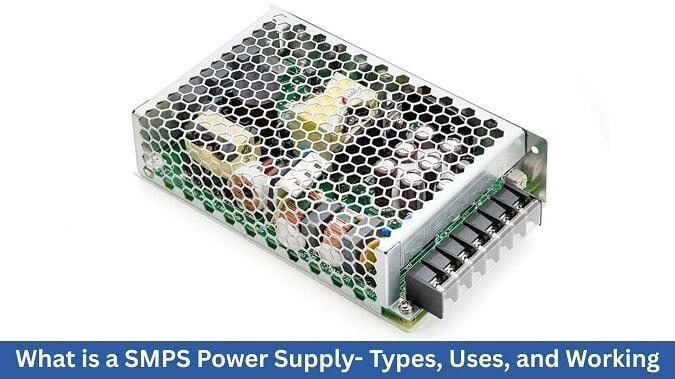

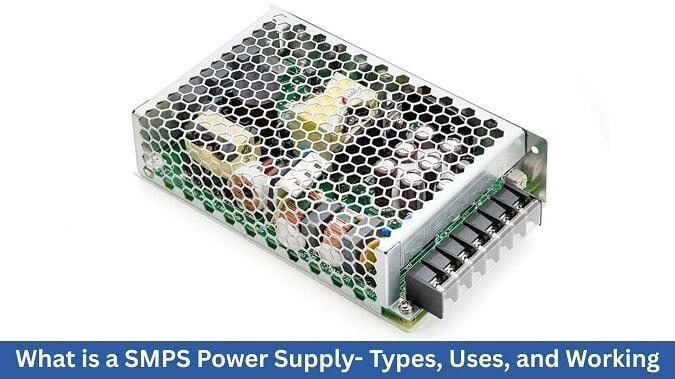

What is SMPS?

Key Components Of a Switch-Mode Power Supply

SMPS circuit consists of various components which is essential for circuit designers and engineers. It includes the following components:

1.Rectifier and Filter

It includes the diodes and capacitors that convert AC voltage into DC voltage. This is an important stage that provides a steady input to the switching section.

2.High Frequency Switch

This section includes the fast switching components like power transistors like MOSFETs, BJTs or IGBTs. These components helps in rapidly turning the direct current on and off at high frequencies (typically at 20kHz to some MHz). This high frequency switching reduces energy loss and allows the use of smaller transformers.

3.High Frequency Transformer

SMPS uses lightweight, compact transformers that are different from conventional transformers and operate at high frequencies. They differ the input voltage from the output voltage and step up or step down the voltage as needed.

4.Output Rectifier and Filter

After the transformer, using ultra-fast recovery diodes, the high-frequency AC is again rectified. To ensure a smooth and stable DC output, the resulting pulsating DC is filtered using inductors and electrolytic capacitors. This stage ensures low ripple and noise, which is essential for sensitive electronic devices like microcontrollers and sensors.

5.Feedback Circuit

For maintaining the regulation, a feedback loop monitors the output voltage and provides real-time adjustments. To send the feedback signals to the control circuit, it uses a voltage divider, an error amplifier and an optocoupler which ensures consistent voltage regardless of load variations.

6.Control IC (PWM Controller)

For driving the switching transistor, the control IC generates Pulse Width Modulated signals. Popular ICs include TL494, SG3525, and UC384,2, which regulate duty cycle, monitor voltage/current feedback, and include features like soft start, undervoltage lockout, and fault protection.

Working Principle of SMPS

Switch Mode Power Supply converts electrical power efficiently by rapidly switching electronic components on and off and regulating the output using energy storage devices like inductors, capacitors, and transformers. Below is the step by step working of SMPS:

1.Firstly SMPS rectify and filter the incoming AC mains voltage to produce an unregulated DC voltage using a bridge rectifier and a filter capacitor.

2.After that, this unregulated DC voltage is fed into a MOSFET or IGBT which is high speed switching device, which turns the power on and off at a high frequency (typically 20kHZ to 1MHz). This process creates a pulsed DC waveform.

3.Then the pulsed DC is passed through a high frequency transformer and it performs two key functions: First, it isolates the output from the input and second is it steps up or steps down the voltage depending on the application.

4.The output of the transformer is again rectified using fast recovery diodes and smoothed by filter capacitors and inductors to produce a regulated DC output with minimal ripple.

5.There is a feedback circuit which constantly monitors the output voltage and compares it with a reference voltage. If any deviation occurs , the PWM controller IC adjust the duty cycle of the switch and maintains the stable output.

Types of SMPS

SMPS are classified based on how power is transferred and regulated and they are as follows:

1. AC to DC Converter SMPS

It is the most commonly used SMPS which converts AC mains power to regulated DC output. It includes the processes like rectification, filtering, switching and voltage regulation stage. They are used in computers, televisions, mobile chargers, LED drivers etc.

2. DC to DC Converter SMPS

This SMPS is used when both the input and output voltage is DC voltage. It steps up (boost), steps down (buck) or inverts the voltage using high frequency switching. It is also called a buck-boost converter. They are used in battery-operated devices, embedded systems and automotive electronics.

3. Flyback Converter

This SMPS stores energy in a transformer during the switch on period and releases it during the off period. It is a cost effective and simple isolated SMPS. They are used in low power supplies, standby power units and small chargers.

4. Forward Converter

This SMPS transfers energy directly to the load during the switch-on phase and uses an output inductor for continuous energy supply. They are used in medium power supplies, telecom equipment, industrial systems etc.

5. Push Pull Converter

This type of SMPS has two transformers that alternately switch the transformer by offering high power and better transformer utilization. They are used in high power inverters, audio amplifiers and communication systems.

6. Half Bridge and Full Bridge Converters

These SMPS are made up of advanced topologies for handling higher power with better efficiency and reduced transformer size. Its applications are high power industrial supplies, UPS systems, motor drives etc.

Advantages of Switch Mode Power Supply

1. SMSP are highly efficient and offer up to 80% to 90% efficiency which is higher than traditional linear power supplies. The high frequency switching reduces power loss and heat generation.

2.As SMPS uses high frequency transformers and smaller components, it is more compact and lighter compared to bulky linear supplies.

3.SMPS is able to handle wide range of input voltages (90V – 270V AC) which makes it suitable for various applications globally with fluctuating power supply.

4.SMPS delivers a precise and stable DC output voltage with the help of PWM control and feedback loops even under varying load and input conditions.

5.Advanced techniques like filtering and shielding which allows SMPS to operate with minimal Electromagnetic Interference and noise which is essential for sensitive electronic components like sensors, microcontrollers and wireless modules.

Disadvantages of Switch Mode Power Supply

1. SMPS are more complex compared to linear power supplies in terms of design and component count. They require additional parts like control ICs, high speed switches and transformers.

2. Due to its complex design and manufacturing costs, SMPS are more expensive.

3.Even with filtering, SMPS outputs can have residual switching noise and voltage ripple, which can be problematic for high-precision analog circuits, audio systems, and RF applications.

4. Troubleshooting or repairing of an SMPS is more difficult due to its complex design.

Applications of Switch-Mode Power Supply

1.SMPS is the backbone of modern computers, used for powering the motherboards, CPUs, and hard drives by converting AC mains to multiple regulated DC voltages.

2. SMPS are also used in powering the LED TVs, set-top-boxes, gaming consoles, and mobile chargers.

3.SMPS are also used in industrial automation systems like PLC systems, motor controllers, and CNC machines to supply stable voltage with protection features in harsh industrial environments.

4.In telecom towers, routers, switches, and networking gear, SMPS ensures constant power with low noise, essential for uninterrupted signal transmission.

FAQs- Switch Mode Power Supply

1. Why is SMPS more efficient than a linear power supply?

SMPS is more efficient than a linear power supply because it uses high-frequency switching to minimize energy loss and heat generation.

2. What is the difference between isolated and non-isolated SMPS?

The difference between isolated and non-isolated SMPS is that isolated SMPS uses a transformer to separate input and output electrically, while non-isolated SMPS connects them directly without galvanic isolation.

3. Why do SMPS generate electromagnetic Interference (EMI)?

SMPS generates electromagnetic interference (EMI) due to high-frequency switching of power transistors, which creates rapid voltage and current changes.

4. What is power factor correction (PFC) in SMPS?

Power Factor Correction (PFC) in SMPS is a technique used to improve the power factor by aligning the input current phase with the input voltage, reducing reactive power and enhancing efficiency.