What is PLC in Electrical?

A PLC, a programmable Logic controller, is a digital industrial computer in electrical engineering. PLC is designed to control, monitor, and automate the electrical processes, machinery, and systems.

It receives the input signals from sensors, switches, and electrical devices, and then processes them with the help of programmed logic before sending the output signal to actuators, motors, and relays.

It is also called the brain of an automation system. PLC uses programmable memory for executing logic-based instructions. This makes PLCs more flexible, efficient, and reliable for automation, unlike traditional relay-based control panels.

PLC Architecture

PLC architecture is made up of electronic components like power supply, processor (CPU), input/output modules, memory, and communication interfaces.

1.Central Processing Unit (CPU)

The CPU executes the control program and acts as the brain of the PLC. It contains the Arithmetic Logic Unit (ALU), which processes input data, applies logical instructions, and generates the required outputs. The control unit present in the CPU helps with sequencing and internal timers/counters.

2.Memory Unit

PLC contains the memory unit for storing the user program, operating system, and data. It includes the memories like RAM (temporary storage) and ROM/EEPROM (permanent program storage).

3.Power Supply Module

Power supply module ensures a stable power supply is provided, even under electrical disturbances or not. It provides 24V DC voltage to operate the CPU and input/output modules.

4.Input Output Modules

Input modules receive signals from sensors, switches, and electrical devices and convert these real-world signals into a form the CPU can understand/process. The output module sends control signals from the CPU to actuators, relays, motors, and other field devices. The outputs can be digital or analog.

5. Communication Interfaces

PLC uses protocols such as Ethernet, Modbus, Profibus, and CAN bus, with which PLCs exchange data with external systems like HMIs, SCADA, computers, and other PLCs.

6.Programming Device

A programming device is used to develop, upload, and modify the control logic in the PLC.

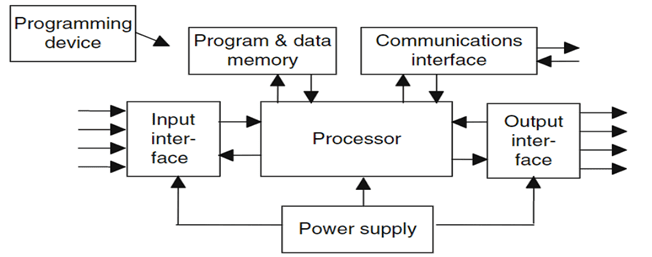

Block Diagram of PLC

1. Power Supply Block

It provides the required DC voltage (commonly 24V DC) to power the CPU and I/O modules & ensures stable operation even during voltage fluctuations.

2. Input Block

PLC interfaces with sensors, switches, push buttons, and field devices & converts real-world electrical signals (digital or analog) into logic signals understandable by the CPU.

3. Central Processing Unit (CPU) Block

The CPU is the brain of the PLC that executes instructions. It consists of the control unit (directs data flow and program execution), the arithmetic logic unit (Performs logical and arithmetic operations), timers and counters (manage process delays and event counting)

4. Memory Block

PLC stores the user program, control instructions, operating system, and process data inside the memory block.

5. Output Block

It sends control signals from the CPU to actuators, relays, motors, solenoids, and alarms & converts logic signals back into real-world electrical outputs.

6. Communication Block

It provides connectivity between PLCs, HMIs, SCADA systems, and external computers & supports industrial communication protocols like Ethernet/IP, Modbus, Profibus, and CAN bus.

7. Programming Device Block

External device (PC, laptop, or handheld programmer) used to write, upload, and modify PLC programs.

PLC Working Principle

PLC’s working principle is based on a continuous cycle for controlling the electrical and industrial processes. PLC replaces traditional relay-based systems by using digital programming to execute control tasks with speed, accuracy, and flexibility. Below is the step-by-step working of a PLC:

1.Firstly, through the input module, PLC continuously scans input signals from sensors, switches, push buttons, and measuring devices. These input signals can be digital or analog ones.

2.CPU, the brain of the PLC, processes the input data based on the instructions written in the user program. The CPU performs operations like logical operations, arithmetic functions, timers, and counters.

3.Then the CPU decides the control action by comparing the input conditions with the programmed logic.

4.The processed instruction by the CPU is then sent to the output module, which controls actuators, motors, relays, alarms, solenoids, and other field devices.

5.For communication and monitoring of data, PLCs exchange real-time data with HMIs, SCADA systems, and other PLCs via communication interfaces for monitoring, control, and coordination.

6.This cycle of scanning the input signal, execution of the program, and output update happens continuously while ensuring real-time automation.

Types of PLC

Depending on the design, size, functionality, and application, there are different types of PLCs:

1.Compact PLC

A compact PLC is also known as a fixed PLC in which all components, such as CPU, power supply, input/output modules, and communication ports, are built into a single compact unit. It is a cost-effective and easy-to-install solution. Because of its limited expandability, it is suitable for small-scale automation like elevators, lighting systems, and packaging machines.

2.Modular PLC

Modular PLC offers high flexibility and scalability for complex automation processes because they are built with a modular design where CPU, power supply, and I/O modules are separate and can be added as required. They are used in manufacturing plants, automotive industries, and process control systems where any further expansion is required.

3.Rack-Mounted PLC

Rack-mounted PLCs consist of multiple modules, which are placed on a rack or chassis, wherein each module (CPU, input, output, communication) can be inserted into slots, making it highly expandable. It is suitable for large-scale industrial automation such as power plants, oil refineries, and large assembly lines.

4.Soft PLC

Soft PLCs are software-based PLCs that run on a computer or industrial instead of a hardware controller, which provides virtual control with high flexibility and advanced data processing. They are commonly used in SCADA systems, testing labs, and simulation environments.

5.Safety PLC

These PLCs are specially designed for safety-critical applications, which ensures compliance with international safety standards (like SIL levels). They are used in automotive manufacturing, chemical plants, and robotics, where worker and equipment safety is crucial.

6.Nano PLC/ Micro PLC

Nano PLCs are very small-sized PLCs which are designed for basic automation tasks one handling fewer I/O points, typically below 100, which are suitable for home automation, vending machines, HVAC systems, and small machinery.

Applications of PLC

1. For controlling assembly lines, conveyor belts, robotics arms, PLCs are used in industrial manufacturing plants. PLCs are also used for automating the packaging process, labelling, and quality control.

2. PLCs are used for motor control as well, which ensures safe operations of CNC machines, pumps, and turbines, and protects equipment through integration with relays, overload sensors, and MCBs.

3. They are used in renewable energy systems like solar plants, wind turbines, and hydro power stations.

4. PLCs are used in building automation for managing the smooth working of HVAC systems, elevators, and escalators.

Frequently Asked Questions

1. Where are PLCs Used in Real-World Applications?

PLCs are used in real-world applications such as manufacturing plants, power systems, building automation, transportation, and process control industries.

2.Which Software is Used for PLC Programming?

PLC programming typically uses software like Siemens TIA Portal, Allen Bradley RSLogix, Schneider EcoStruxure, and Mitsubishi GX Works.

3.Is PLC Easy to Learn for Beginners?

Yes, PLC is easy to learn for beginners as it uses simple programming languages like Ladder Logic and offers practical, hands-on applications.

4.Do PLCs Require Maintenance?

Yes, PLCs require minimal maintenance, mainly involving firmware updates, periodic inspections, and ensuring clean power and environment.

5.What are the Advantages and Disadvantages of PLCs?

The advantages of PLCs are reliability, flexibility, and easy automation, while the disadvantages include an initial high cost and the need for skilled programming.

6.Is Coding Necessary to Work with PLCs?

Yes, coding is necessary to work with PLCs, typically using Ladder Logic, Function Block Diagram, or Structured Text programming languages.