What is magnetic starter?

A magnetic starter is a switch which can be operated electrically. They are designed to safely start, stop and protect electric motors from overloads, short circuits and phase failure. Magnetic starter has electromagnetic contactor along with overload relays which ensure automatic and reliable motor control by providing enhanced safety for equipment and operators. The main function of electric motor is to control large electric motors. They handle the high inrush current during the startup by offering built-in motor protection. Magnetic starter is an integrated system made up of miniature circuit boards, connectors, contactors etc. Magnetic starter is widely used in HVAC systems, conveyors and in industrial machines.

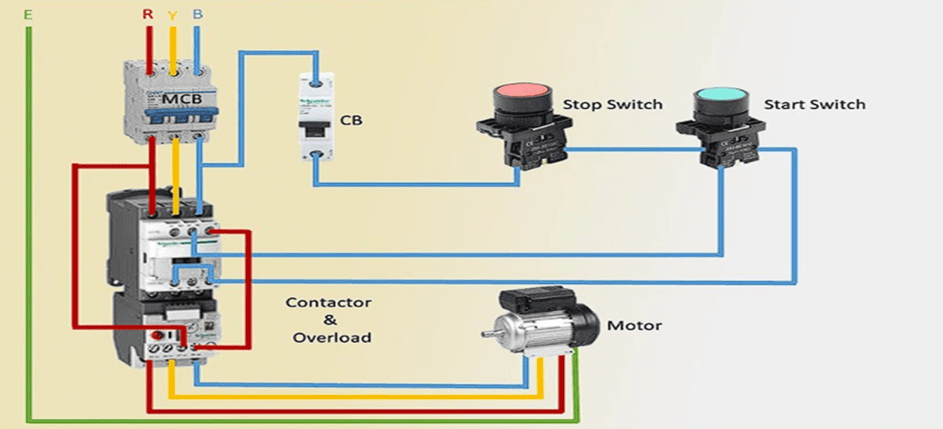

Magnetic Starter Circuit Diagram

Magnetic starter circuit diagram includes the components like contactor, overload relay, MCB, push buttons & motor connections. They are electrically interconnected to control and protect electric motor.

1. Power supply which is usually a three-phase for industrial motors, provides the electrical input.

2. To provide short-circuit and overcurrent protection, MCB is placed before the starter.

3. Electromagnetic switch contactor is used which connects or disconnects the motor from the power supply.

4. Overload relay is used to protect the motor from overheating and current overload conditions.

5. When start push button (Normally Open) is pushed, it energizes the contactor coil to start the motor.

6. When stop push button (Normally Closed) is pushed, it interrupts the coil current to stop the motor.

7. Motor load devices like pump, fan compressor etc is connected to starter.

Function of Starter in Motor

1. During startup of motor, starter limits the excessive inrush current drawn by the motor and prevent damage to windings.

2. Relays connected in starter protect the motor from overheating and current conditions.

3. Starters can control ON/OFF switching of motors.

4. Starter maintains the voltage stability by limiting the high inrush current and protect the other connected equipment.

5. Starters can be operated remotely through push buttons, sensors or automated control systems.

6. During short circuit, phase failure or overload, starters disconnect the motor.

Motor Starter Working

Working principle of motor starter is based on the principle of controlling the flow of electric current.

The motor starter is connected to the main power supply through MCB which provides initial protection against short circuits.

After we pressed the start button, current flows through the control circuit and energizes the electromagnetic coil of starter.

The energized coil pulls the contactor contacts together and allows power to flow from the supply line to the motor windings. The holding contacts keep the circuit closed even after releasing the start button.

After that motor begins to rotate and draws the current which is regulated by the starter. Depending on the type of starter, the inrush current is either directly supplied or reduced.

When motor draws current above its rated capacity, the overload relay trips and breaks the control circuit and de-energizes the contactor to stop the motor.

The control circuit is interrupted when we press the stop button and the coil de-energizes and opens the contactor and disconnects the motor from the supply.

Types of Magnetic Starters

There are different types of magnetic starter which are categorized on their power requirements, protection needs and the application.

1. Direct-On-Line Magnetic Starter

Direct-on-line is a low cost, simple in design and which is easy to install magnetic starter. It supplies full line voltage directly to the motor through a contactor. It can cause high inrush current at startup but highly efficient one and start quickly. It is used in small to medium motors i.e. up to 5 HP.

2. Reversing Magnetic Starter

This type of magnetic starter uses two contactors in such a way that the motor’s rotation can be reversed. It includes electrical or mechanical interlocks which prevent both contactors from energizing simultaneously. They are slightly more complex and has high cost but they provide easy motor direction control. They are used in conveyor belts, cranes and machinery forward and backward motion is required.

3. Star Delta Magnetic Starter

These magnetic starter starts the motor initially in star connection for reducing voltage and then switches to delta connection for normal running. Thay can reduce start current to one-third of direct-on-line start. They require more space, wiring and control equipment. But they prevent voltage dips by limiting the inrush current. They are used in large three phase induction motors i.e. above 5HP.

4. Autotransformer Magnetic Starter

Autotransformer magnetic starter provides smoother acceleration with adjustable voltage tapping. They use an autotransformer to supply reduced voltage to the motor during starting and then switches to full line voltage. They have high initial cost compared to other starters but they have better control of starting torque and reduces mechanical stress. They are used in heavy duty industrial motors where reduced starting current is essential.

5. Compensator Magnetic Starter

Compensator magnetic starter has external resistance in series with the motor during startup and then gradually reduce it as the motor picks up speed. It limits starting current by controlling resistance. They are less efficient and rarely used in modern installations but can provides current limitation and overload protection. They are used in older systems and specific industrial setups.

Applications of Magnetic Starter

Used in conveyor systems, presses, lathes, milling machines, and CNC machines.

Extensively used in water pumps, hydraulic pumps, air compressors, and irrigation systems.

Controls motors in heating, ventilation, and air conditioning equipment.

Magnetic starters are critical for lifting equipment where safe motor control is essential.

Used in irrigation pumps, threshers, and harvesters.

Applied in industrial ventilation, cooling systems, and dust collectors.

Used in large motors for escalators, elevators, central air systems, and water supply pumps.

Frequently Asked Questions

1. What is the difference between a contactor and a magnetic starter?

Ans. A contactor is an electrically operated switch used to control power flow, while a magnetic starter is a contactor with added overload protection for starting and safeguarding motors.

2. Can a magnetic starter be used without overload protection?

Ans. No, a magnetic starter should not be used without overload protection as it is essential to safeguard the motor from overheating and damage.

3. Is a magnetic starter AC or DC?

Ans. A magnetic starter is primarily designed for AC motors, though its control coil can be either AC or DC depending on the application.

4. What size of motor requires a magnetic starter?

Ans. A magnetic starter is typically required for motors above 5 HP to handle high starting current and provide overload protection.

5. What is the voltage rating of a typical magnetic starter?

Ans. The voltage rating of a typical magnetic starter usually ranges from 220V to 600V AC, depending on the motor application.