Ubintex, a leading connectivity solution provider, provides terminal block connectors with accuracy for a wide range of applications. Ubintex has provided the most trustworthy, dependable, and professional connectors. Ubintex's world-class connections aid you in making your technological items a miracle, outsmarting the worldwide market. Ubintex makes the connection simple at a reasonable price. They have it all, from cable goods and assemblies to PCB card sockets. You need the best connections to enable your unique products in various applications such as server, storage, data centre, networking, industrial, commercial equipment, and automotive. Ubintex offers a competent team of specialists and highly experienced engineers that comprehend design specifications and deliver turnkey solutions.

Terminal Block:-

A terminal block is a modular housing with an insulated body that connects two or more wires. Terminal blocks, also known as terminal connectors, connection terminals, or screw terminals, are used in applications where electrical systems must be appropriately linked.

They are perfect for systems that require secure, well-organized, and semi-permanent wire connections that can be quickly switched out in the field for inspection or repair.

Types of terminal blocks:

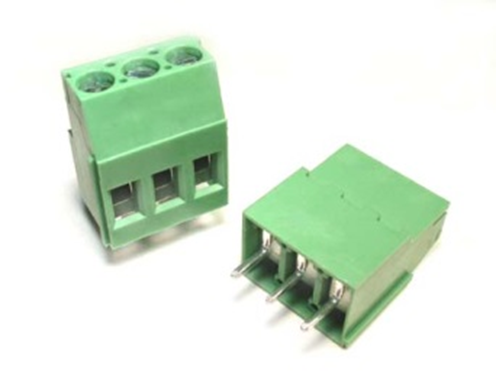

1. PCB Screw Terminal block

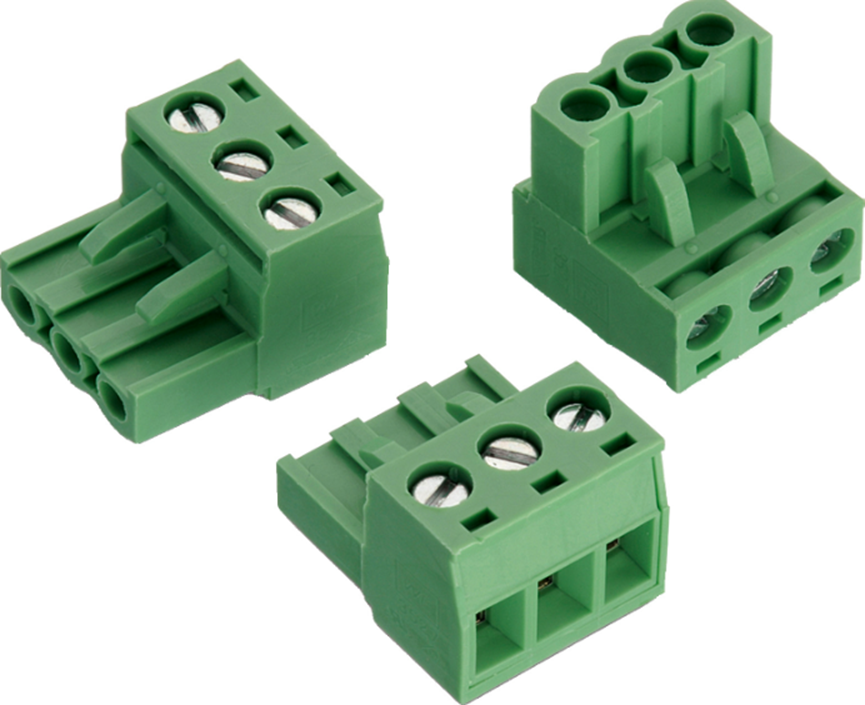

2. Plug in terminal block

3. Barrier Terminal Block

4. Push-fit Terminal Block

5. Spring-cage terminal block

6. Ground terminal block

7. Fuse terminal block

8. Thermocouple terminal block

1. PCB Screw Terminal Block : PCB terminal blocks enable the easy and safe transmission of signals, data, and power to the PCB. They are suitable for a variety of applications in numerous industries, markets, and for Industry 4.0 applications.

2. Plug in terminal Block: The plug-in COMBI terminal blocks are a special form of hybrid terminal blocks. The terminal blocks have a standardized plug-in zone on one side and Push-in, screw, spring-cage or fast-connection technology on the other side. Due to the contact system, they can withstand extreme vibration levels. The plug-in terminal blocks save you a lot of time when carrying out signal and power wiring.

3. Barrier Terminal block: Barrier Blocks are designed to simplify wiring work by reducing splicing, preventing current leaks and short circuits, and increasing insulation. Available in a variety of densities, these barrier blocks can be found in applications ranging from industrial controls to switching systems.

4. Push-fit Terminal Block : The Push-fit or Push in terminal block is becoming very popular. Much like the Spring-Loaded terminal block, the “Push-fit” often requires the wire to be covered by a ferrule. Several vendors make Push-fit terminal blocks. A connection is made by simply inserting the wires. The big difference between the Spring-loaded and the Push-fit terminal block is the method of wire release. Push-fit terminal blocks have the release device mounted right next to the wire insertion point.

5. Spring-cage terminal block: Another common method for wire connection is the Spring cage terminal block. A connection is made by simply inserting the wires. Most of these terminal blocks require the wire to be attached to a ferrule before it is inserted. The ferrule or wire is attached and released by inserting a spring release device. Some vendors have a unique spring release device while others require a small screwdriver.

6.Thermocouple terminal block: A Thermocouple terminal block is designed to accept thermocouple lead connections. Thermocouples cannot be connected to typical terminal blocks. As soon as the thermocouple wire makes contact with the conducting material inside the terminal block an unwanted junction occurs. Any dissimilar metals joined together will create a new junction, and consequently an unwanted voltage.

Selection guide for terminal block:-

When designing a system that will utilize a terminal block, you will likely know your overall system voltage and current requirements. While these are very important, there are other factors to consider in your design as detailed below.

Current Rating:-

The current rating is often the most important parameter to consider in terminal block designs. The current rating is based on the conductivity of the terminals, cross-sectional area, and the corresponding heat rise. Operating at too high of a current can cause overheating and damage of the terminal block, leading to major safety concerns. It is best practice to use a terminal block that is rated for at least 150% of the max current that is expected in the system.

Voltage Rating:-

The voltage rating is in part determined by the dielectric strength and pitch of the terminal block housing. The maximum system voltage of the application must be less than the voltage rating. Any voltage surges in the system should also be evaluated when selecting the terminal block.

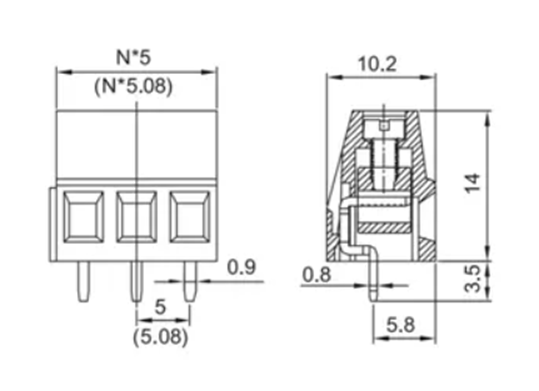

Pitch:-

A terminal block’s pitch is defined as the center distance from one pole to the next. The pitch of the connector is often determined by the overall rating of the terminal block where factors like voltage/current, creepage, and clearance are considered. Common industry pitches would be, but are not limited to, 2.54 mm, 3.81 mm, 5.0 mm, and 7.62 mm. Comment: (you can explain by using diagram also)

Wire Size/Type:-

The minimum and maximum wire size that the terminal block can accept would be a function of the voltage/current rating. In addition to making sure the wires used will physically fit into the terminal block, the type of wire should also be considered. Stranded or multi-core wire is typically used for screw terminals, and single-core is typically used for push-in style terminal blocks. In North America wire size is specified in units of American wire gauge (AWG).

Key Terminal Block Mechanical Considerations:

In addition to system electrical factors, mechanical restrictions and limitations need to be considered in terminal block design. The key features to consider are any mechanical restrictions on the housing of the design that may impact overall footprint, orientation, and accessibility of the connections. Mechanical variations on the housing can include, but are not limited to, the following.

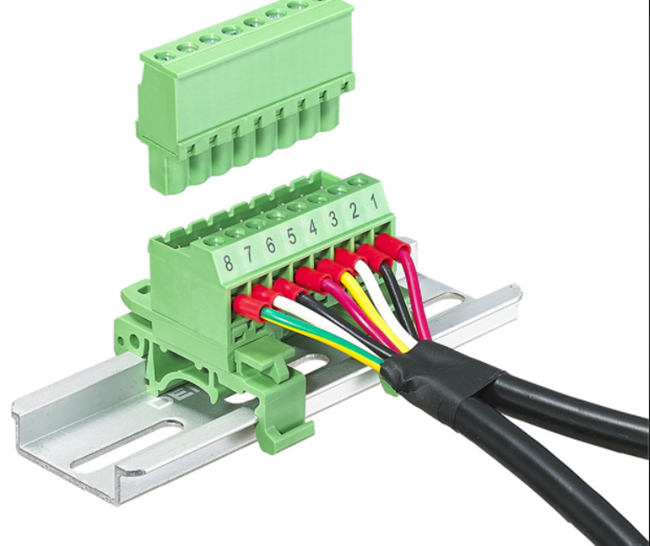

Terminal blocks mounting:-

Terminal blocks are mounted in a variety of ways but by far the most common is by attachment to a DIN Rail and PCB Mounting. A Din Rail is a metal rail of a standard size universally used for mounting devices and components inside electrical panels and equipment racks.

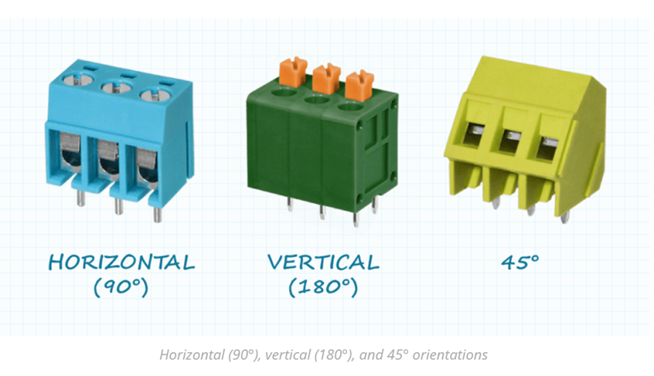

Wire-Entry Orientation:-

Terminal blocks come available in three common orientations: horizontal, vertical, and 45°. Horizontal and vertical are also known as 90° and 180°, respectively. The wire orientation can often be determined by physical restrictions in the overall design that make one option more feasible.

Wire Securing Method:-

The method in which the wires are secured in the terminal block housing are typically accomplished by three main types: Screw Terminal , Push Button and Push In

Screw Terminal: Screw terminal or screw type terminal blocks secure the wire against the conductor in the terminal block by tightening a screw which closes the clamp.

Push Button:- Push button terminal blocks secure the wire against the conductor by a spring clamp that is opened by pressing a button. Releasing the button clamps the spring onto the wire.

Push-In:- Similar to the push button with a spring clamp, a push-in terminal block allows the wire to be pressed directly into the housing without the use of a push button to open the spring.